Polymer production

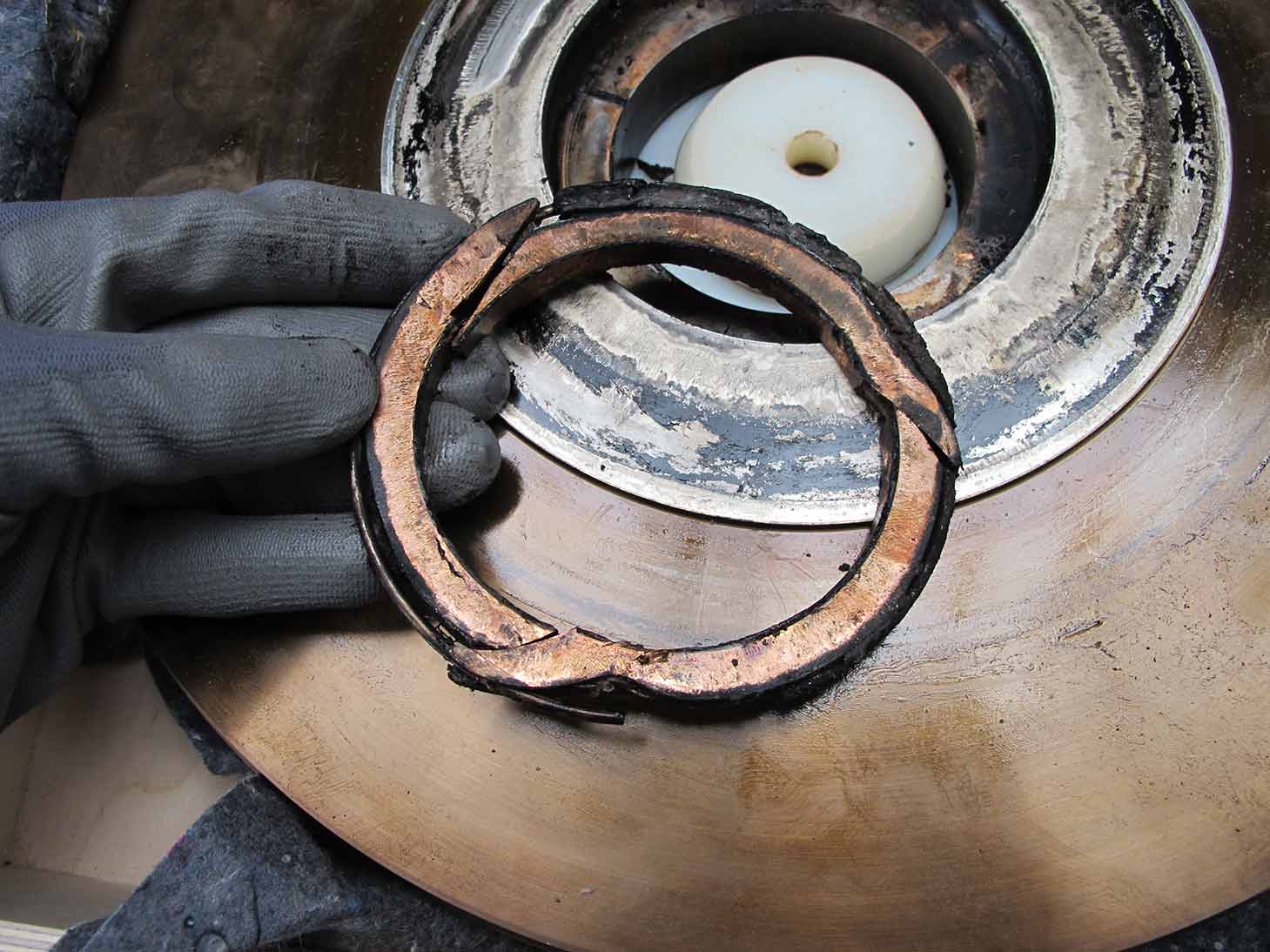

In combinations with the refurbishment of hyper compressor plungers, CTD ha set up a repair service for hyper compressor packing cups. Packing cups have to seal the extremely high pressure gas in the cylinder and are therefore prone to fretting fatigue. The fretting fatigue can lead to cracks that can grow to the outside of the cup which can lead to gas leaks. It is thus very important that the cups are inspected and reconditioned on regular bases.

Provided services

The failure analysis of cup defects in combination with plunger analysis makes it possible to perform a better RCA of your compressor problems. Defect reports with photo’s of the packing condition and defects are made of each cup.

Reconditioning of a complete set of packing cups takes about 1 month including lapping, shot peening and silver plating. Depending on the operations that we have to do, the delivery time can be reduced. This short delivery time makes it possible to reduce the number of your spare parts, reducing the overall operating cost.

CTD supplies special bronze seal rings, pressure breaker rings and guide bushes according to customer specifications. In order to provide the best combination in sealing properties, strength and wear resistance, special bronzes have been developed. Different lead contents guarantee proper operation during inadequate lubrication conditions like during start-up. Tangential rings can be supplied in 3 or 6 piece design.