Metal Packaging

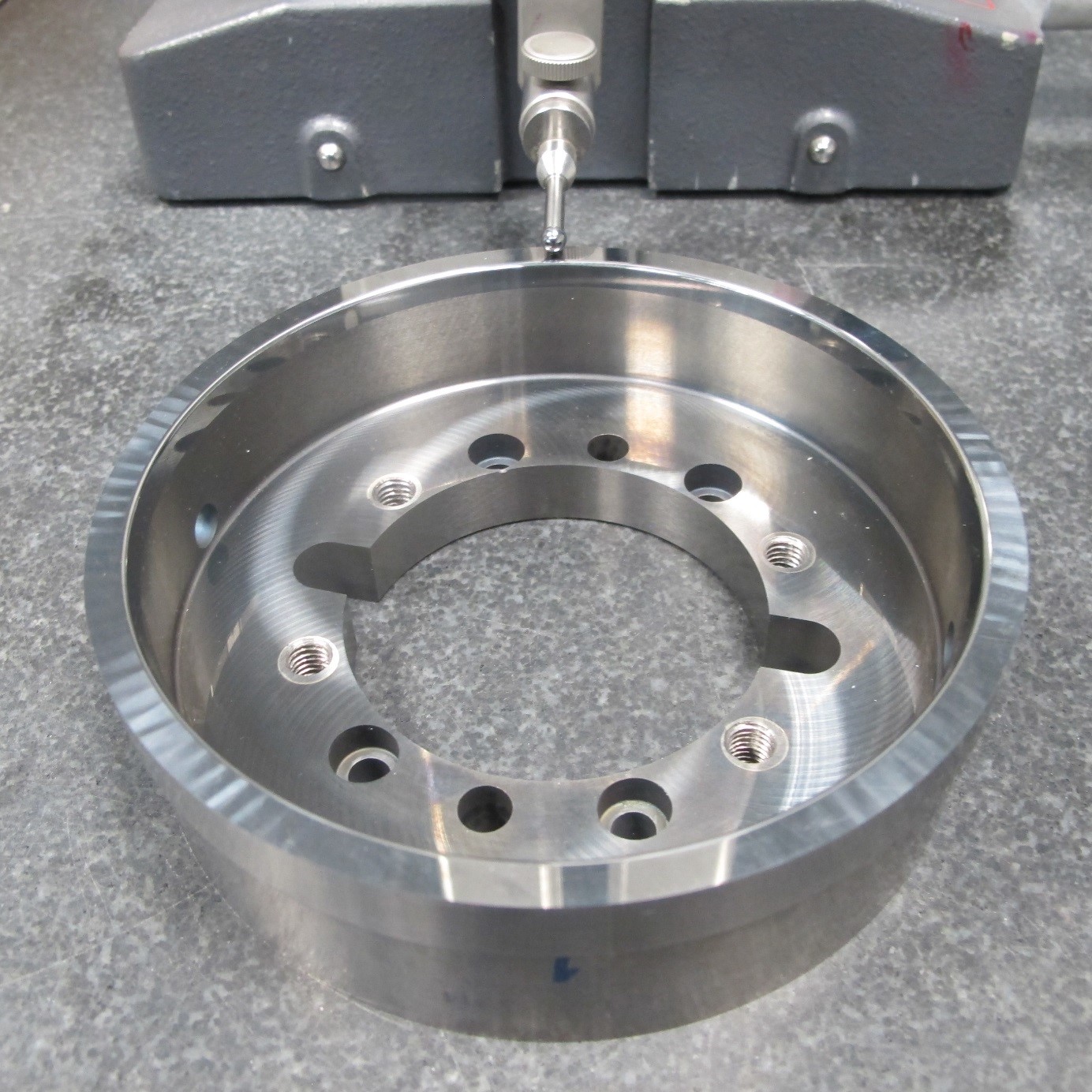

Metal food cans come in a wide variety of shapes and sizes. This diversity requires a large number of tooling. In order to reduce costs, most of the tooling consist of a steel body with a carbide insert that provides wear resistance and dimensional stablity for forming, deep drawing and cutting of tinplate or aluminium. CTD has the know-how to assemble and machine both materials. Our wire and sink EDM machines and the CNC cylindrical and surface grinding machines are all designed for machining carbide materials. This makes it possible to manufacture and refurbish all food can and aerosol tooling in house.

Carbide tooling is found in the different production stages. Typical applications are:

CTD manufactures tools and dies for aluminium slug extrusion with special carbide grades to obtain smooth surfaces on the aluminium aerosols. We also make carbide tools for 2 and 3 piece steel aerosols.