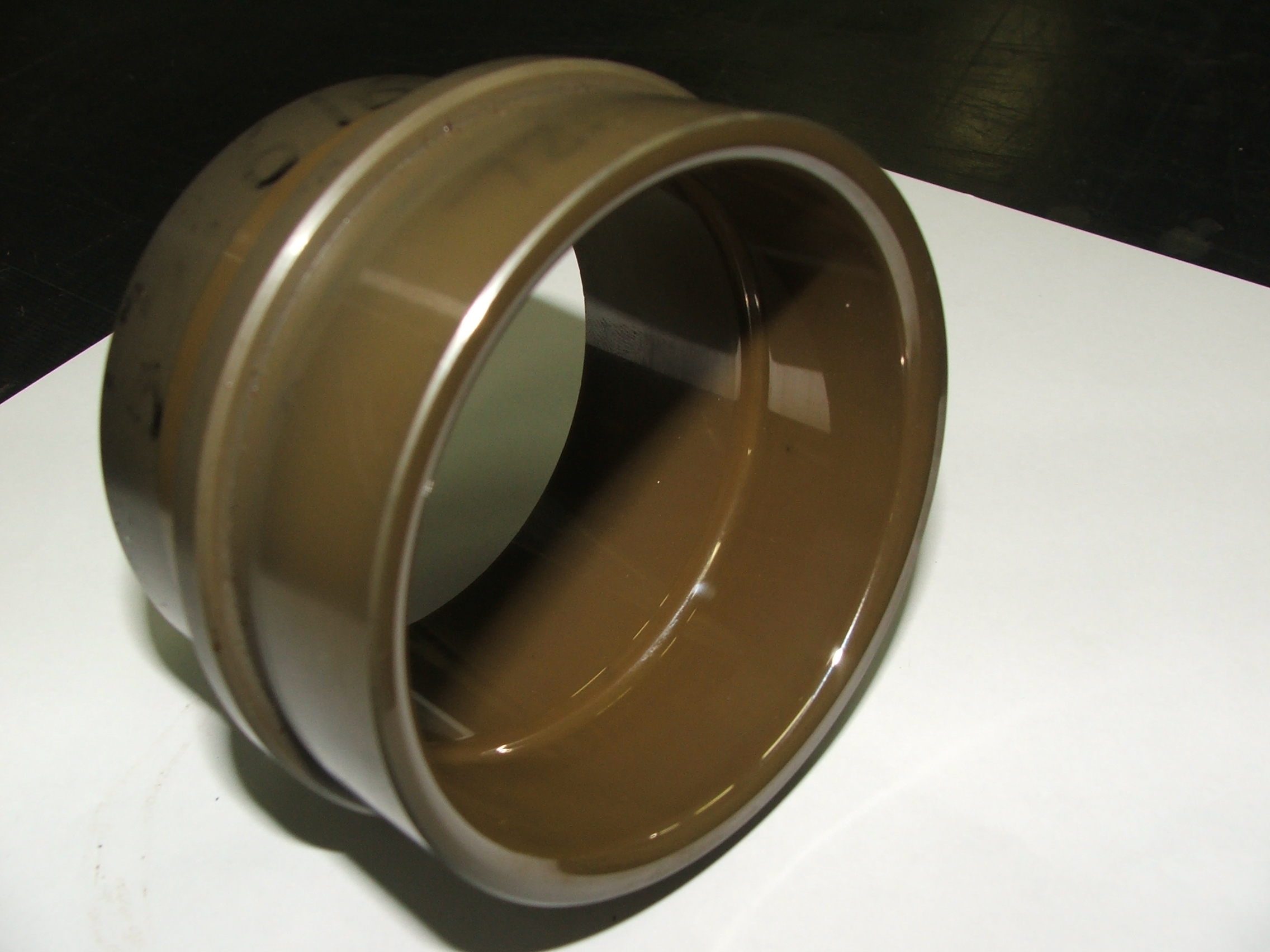

Metal Packaging

Beverage cans are produced at speeds of up to 450 cans per minute. This requires highly wear resistant tooling with micrometer tolerances, smooth profiles and sharp cutting edges. Cemented carbide has proven to be the perfect material to maintain these close tolerances for a longer time. CTD has the precision machines and measuring equipment combined with the know-how to manufacture these tools. We manufacure tooling for steel and for alumium cans with specific surface finishes. We are not only manufacturing new tooling, but we also provide regrinding of existing tooling in order to reduce the total life cycle cost of your tooling.